Specialty mushrooms, such as shiitake, oyster, and lion’s mane, are growing in popularity. The value of U.S. sales for commercially grown specialty mushrooms in 2021-2022 totaled $87.3 million; up 32% from the previous season. (The popular commodity mushrooms: button, cremini, and portobello are not considered to be specialty mushrooms by the USDA.)

Because of their delicate nature and perishability, specialty mushrooms are ideal as a local crop. They require gentle handling, packing and shipping. In this way, they are like heirloom tomatoes - difficult to successfully mass cultivate and ship, perfect, though, for smaller local growers and shorter shipping routes.

This fact sheet outlines production practices that mushroom growers can take to boost quality and shelf life that at the same time lower the risk of contamination with illness-causing germs. Ensuring the safety and high quality of these mushrooms is crucial for both consumers and producers.

Preventing Contamination

Microorganisms – the good, the bad, and the ugly, are almost everywhere in the production chain. Spoilage and illness-causing germs can be in air, soil, water, manure, feces, human handling, animals, dust, harvesting equipment, transportation equipment, and processing equipment.

Effective strategies can protect your crop and keep quality high and food safety risks low. For example, harvesting mushrooms with clean hands prevents contamination from harmful bacteria and viruses, and from spoilage bacteria, yeasts and molds that may be on unwashed hands.

Using best practices in these essential areas will support quality, shelf life, and lower food safety risk in specialty mushroom harvest:

- Worker Personal Hygiene/Health

- Pest Intrusion

- Water Quality

- Sanitary Handling of Harvest Containers, Surfaces, Tools

- Grow Room Sanitation

- Refrigeration

- Market Packaging

- Transportation

- Documentation

Worker Personal Hygiene/Health

Similar to conventional crop production, worker training should include washing hands with clean water and soap for 20 seconds before harvesting and handling mushrooms, after using the toilet, after eating or touching hair or face, electronic devices or anything that may contaminate hands.

Workers should be trained to bandage cuts and dispose of mushrooms that may have been contaminated with blood or other bodily fluids, as well as to clean and sanitize any tools or surfaces that may have been contaminated.

To prevent spreading germs to the mushrooms and contaminating them, workers who are ill should not handle mushrooms. Workers with symptoms of vomiting, diarrhea, contagious infections, or jaundice should stay home.

Pest Intrusion

In log-grown mushroom production, pests may include squirrels, snails, and even deer. If they snack on your mushrooms, besides bite damage, they can also leave harmful bacteria behind. Contaminated mushrooms must not be sold.

To prevent pest damage, log-grown mushroom farmers use a combination of methods including stacking logs off of the ground, such as on a pallet. Covering logs with air and water-permeable agricultural cloth keeps pests away while helping to keep logs productive by preventing them from drying out. Regular monitoring is needed to check on the logs to make sure the covering remains secure, and the logs protected.

Indoor mushroom production has an easier time in this respect, as pest intrusion into the production area is prohibited with secured doors and windows. Within the grow rooms, the mushrooms are protected from these woodland pests.

Still, indoor mushroom contamination from fungal, bacterial, and viral pathogens can be prevented or limited with the sanitary measures discussed in this fact sheet. A monitoring program and Integrated Pest Management (IPM) plan can assist with managing any insect pests that may infiltrate your indoor crops.

Water Quality Considerations

The quality of the water used affects the quality and safety of the mushroom crop.

Whether growing inside or outside, clean water, with zero detectable Escherichia coli (E. coli) is needed for humidifying the grow room and cleaning hands, tools, work surfaces, and containers that the mushrooms contact.

All surfaces that may contact mushrooms need to be clean to help keep spoilage yeasts and molds and illness-causing organisms from contaminating your mushrooms.

When growing outside on logs, growers should be aware of what is happening upstream or in the pond or other surface water source where the logs are soaked.

For instance, toxic materials could be absorbed by inoculated logs soaking in a polluted water source and then taken up by the mushrooms as they develop.

Sanitary Handling of Harvest Containers, Surfaces, Tools

Properly cleaning work surfaces, tools, and containers means scrubbing surfaces with soapy water and rinsing with clean water on a regular schedule.

After cleaning and rinsing, sanitizing tools, surfaces, and totes with a food grade sanitizer adds an extra level of protection against contamination. Using cleaned tools and harvesting into clean single-use containers or cleaned and sanitized reusable containers keeps contamination risk low.

Note: Growers who choose to use sanitizers need to become familiar with the regulations regarding their use.

All harvesters should wash their hands with water and soap before harvesting. Proper glove use adds another layer of sanitary handling. Gentle handling prevents bruising which causes brown discolored tissue to develop.

Log grown mushrooms may need to be wiped off with a clean paper towel or a clean, soft brush, if needed.

Indoor-grown mushrooms only need the growing substrate trimmed off.

Grow Room Sanitation

Mushroom grow rooms, like any produce facility where humidity is used to manage quality, are a favorable environment for illness-causing bacteria, in particular, Listeria monocytogenes (Lm), to flourish.

Although the number of people infected by foodborne Listeria is comparatively small, this bacterium is one of the leading causes of death from foodborne illness.

It comes in two different forms:

One has symptoms such as nausea, vomiting, aches, fever, and, sometimes, diarrhea, and usually goes away by itself.

The second, more deadly form of infection spreads through the bloodstream to the nervous system (including the brain), resulting in meningitis, miscarriages, and other potentially fatal problems.

Listeria and other harmful microbes can form difficult-to-remove protective coatings called biofilm. Removing biofilm requires “elbow grease” and scrubbing with detergent and clean water then rinsing thoroughly to disrupt and remove the biofilm structure. Applying sanitizer to a surface cleaned in this way is an additional strategy to control biofilm formation.

A regular grow room cleaning and sanitizing schedule should focus on these areas:

- Floors, especially cracks and crevices

- Drains

- Wet insulation in walls or around pipes and cooling units

- Rubber seals around doors

- Removing standing water

Refrigeration

When appropriate cold conditions are maintained during storage and transport, freshly harvested mushrooms keep their quality for longer. Proper refrigeration minimizes dehydration, spoilage, and bacterial growth. Leaving mushrooms unrefrigerated for too long can cause them to dry out and their quality decreases quickly. Bacterial blotch or Pseudomonas spp. can become a problem during extended storage at elevated temperatures.

According to USDA Agriculture Handbook Number 66, optimum storage conditions for mushrooms require rapid cooling and storing at 32° to 34°F with 95% Relative Humidity (RH). These conditions result in a 7 to 9 day shelf life.

Storing at just a few degrees warmer, at 36°F, shortens storage life to 3 to 5 days by accelerating surface browning, stipe (stem) elongation, and veil opening.

High relative humidity is essential to prevent dehydration and loss of glossiness. Moisture loss leads to stipe blackening and veil opening.

When planning farmers’ market sales, mushrooms should be stored cooler than 40°F. A refrigerator thermometer in an ice-pack filled cooler can be helpful for monitoring temperature.

Market Packaging

Do not seal mushrooms in an airtight container. Mushrooms have very high rates of respiration, and packaging must provide enough air flow to avoid fermentation, which speeds spoilage and results in a slimy, unpleasant texture. Very low oxygen levels can promote the growth of Clostridium botulinum and the development of off odors and off flavors.

A paper bag or slotted berry basket or box that allows free air flow works well. Reusing cleaned and sanitized containers can work also. If the reusable container is not able to be cleaned, for example, if it is a cardboard harvest box, best practice is to line the container with a fresh liner, such as parchment, wax paper, or a paper bag, to separate the freshly harvested mushrooms from any contamination remaining from previous uses.

Transportation

Coolers with ice packs can be used effectively to keep mushrooms fresh and cold during transport to farmers’ markets and other outlets. The transportation vehicle should be cleaned out before the coolers are placed in it. This will help to reduce the risk of contamination of the mushrooms, people handling the mushrooms and coolers in the vehicle’s storage area.

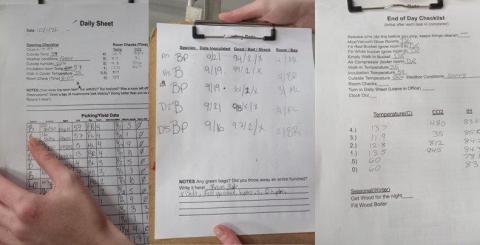

Documentation

Using Standard Operating Procedures (SOPs) and checklists for monitoring and documenting temperatures, quality, and cleaning schedules, makes keeping track of what the mushrooms require at each stage of growth easier to monitor effectively. Mushroom growth cycles are faster than conventional crops. Daily scheduled monitoring can mean the difference between having the highest quality mushrooms to offer and losing a crop to undetected pests or past-its-prime product.

Conclusion

Specialty mushrooms are a valuable and delicious food source, especially suited to the careful handling and short distances to market that local farms can provide. The same steps you use to reduce food safety risks will support highest quality and longest shelf life for this crop.

This fact sheet presents good agricultural practices and good handling practices that mushroom farms of all sizes can use to reduce produce safety risks and increase the quality and shelf life of the produce they grow and handle.

It is complementary to the Food Safety Modernization Act’s Produce Safety Rule (FSMA PSR).

The PSR establishes science-based minimum standards for the safe growing, harvesting, packing, and holding of fruits and vegetables grown for human consumption. Under the PSR, a produce farm falls under one of three categories, “not covered”, “qualified exempt” or “covered”.

To determine where a farm falls and what practices are required in each category, this tool can help: https://unh.az1.qualtrics.com/jfe/form/SV_3HPoZ7BBAnshE8d

No matter which PSR category, utilizing these best practices will help to lower produce safety risks and improve quality.

This Fact Sheet is supported by the Food and Drug Administration (FDA) of the U.S. Department of Health and Human Services (HHS) as part of a financial assistance award #U2FFD007437-02 totaling $645,394 with 100 percent funded by FDA/HHS. The contents are those of the author and do not necessarily represent the official views of, nor an endorsement, by FDA/HHS, or the U.S. Government.

References

- Beyer, D., Fleischer, S., Coles, C., (2002) Pennsylvania Mushroom Integrated Pest Management Handbook https://www.americanmushroom.org/clientuploads/IPM/mushroomIPMhandbook…

- Cornell Small Farms Program (2001-onward) Specialty Mushrooms https://smallfarms.cornell.edu/projects/mushrooms/

- Fay ML, et.al. (May 2023) Modeling the Fate of Listeria monocytogenes and Salmonella enterica on Fresh Whole and Chopped Wood Ear and Enoki Mushrooms, Journal of Food Protection, 86. https://www.sciencedirect.com/science/article/pii/S0362028X23067479

- FDA, (2012). Bad bug book, Foodborne Pathogenic Microorganisms and Natural Toxins Handbook. 2nd ed. US Food and Drug Administration https://www.fda.gov/food/foodborne-pathogens/bad-bug-book-second-edition

- Gross, K., Wang, C. , Saltveit, M., Editors (Rev. 2016) The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks United States Department of Agriculture, Agricultural Research Service, Agriculture Handbook, Number 66 https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf

- Kapahi, M., Sachdeva, S. (2017) Mycoremediation potential of Pleurotus species for heavy metals: a review. Bioresources and Bioprocessing, 32. https://doi.org/10.1186/s40643-017-0162-8

- LaBorde, L. (March 2023 update). Control of Listeria monocytogenes In Mushroom Growing and Packing Environments. Penn State Extension. https://extension.psu.edu/control-of-listeria-monocytogenes-in-mushroom…

- National Agricultural Statistics Service, United States Department of Agriculture, Mushrooms, Agricultural Statistics Board, August 26, 2022 https://www.nass.usda.gov/Publications/Todays_Reports/reports/mush0822…

About the Author

Mary Saucier Choate, Food Safety Field Specialist with UNH Extension, Grafton County, is also a Registered Dietitian/Nutritionist with 24 years of service in the retail food and food safety fields. She works with produce farmers to assist them with identifying and lowering potential produce safety risks. Mary is a ServSafe® certified instructor and proctor. She teaches food safety classes for food workers in food service establishments, schools, food pantries, and other nonprofit organizations.

Contact Information

Mary Saucier Choate

603-787-6944

Mary.Choate@unh.edu

Download this Fact Sheet [PDF]