When air-drying green lumber a specified period of time or holding green inventory long enough for loss of value to occur, it is recommended to place “pile covers” on the lumber packs, to minimize lumber defects and discoloration resulting from exposure to the elements. While there are ample resources providing instructions on constructing pile covers, few address the trade-offs of material selection. This publication presents design and operational considerations for all sizes of lumber producers who are planning to invest time and money in fabricating pile covers. Employee safety and wellbeing should always be the first consideration of any sawmill management team. Any recommendations in this publication should first be verified that they adhere to federal and state occupational health regulations.

Degrade or loss of value of lumber stored in air-dry yards typically range from $21 – $54 per thousand board foot (MBF) and can easily reach $150 per MBF in poorly operated air-dry yards (Wengert 2006). Use of pile covers on stickered lumber, such as the ones shown in Figure 1, help to protect the top courses of lumber from undesirable discoloring and staining associated with sunlight and precipitation (Rietz 1970). Lumber producers should consider costs of the materials, timing of the outlay and return of capital, and operational efficiency in the lumber yard when considering the preferred materials to use for pile covers.

Figure 1. Pile covers in an air-dry yard help preserve the quality and value of the lumber by protecting the lumber from the elements. Photo source: Coos Forest Products.

The ideal characteristics of materials to use in the fabrication of pile covers are (1) longlasting, (2) easily repaired if damaged, and (3) readily available at a minimal cost. Most sawmills generate low-grade lumber and small dimension pallet cants that are ideal for constructing pile covers.

The minimal loss of revenue from using the materials in pile cover construction will be offset by the reduction of defects and discoloration of lumber during airdrying (McMillan and Wengert 1977). A 1966 study of air-drying practices in central Appalachia identified that red oak lumber piles with roof covers had, on average, lumber degrade losses of $3.38 per MBF in comparison to uncovered red oak piles that averaged devaluations of $15.50 per MBF (Cuppett 1966). This disparity in degrade can be attributed to fungus stains and sticker stains more easily developing when the lumber is repeatedly exposed to rain or snow (Rietz and Page 1971). In addition, fluctuations in moisture content caused by repetitive drying and moisture absorption exacerbates shrinkage defects – particularly splitting and checking that reduces lumber value (Forest Products Laboratory 1999).

Species such as ponderosa pine (Pinus ponderosa) and hard maple (Acer saccharum) are especially susceptible to darkening of the wood color which can substantially lower the market value of the lumber (Dawson-Andoh et al. 2004, Wagner et al. 2008). Ultraviolet light from the sun is a significant contributor to undesirable changes in lumber color (Kreber 1994). Pooling of water on lumber surfaces from rain or snowmelt can also be a factor in discoloration (Forest Products Laboratory 1999). An investment in pile covers can help enterprises maximize the value of the lumber produced.

Figure 2. Pile covers fabricated with low-grade lumber fastened to small pallet cants. Photo source: Patrick M. Rappold.

Regardless of the roofing material that will be applied, it is recommended that pile cover construction start with a solid base consisting of 4-inch wide by 3½ -inch thick pallet cants. The pallet cants should be equal distance apart, with adequate space for the various width of forks on the different forklift types that will be used to move pile covers and lumber packs. Depending upon the roofing material, use of pallet cants for the base, can enable the pile covers to be stacked as shown in Figure 2. It is advisable that high-volume air-dry yards adopt a pile cover design that is stackable as it will assist in keeping the yard areas organized and optimize space. A thorough review of literature on best practices for lumber air-dry yards did not produce any recommendations that identified a need to align the lumber stickers and the pallet cants that comprise the base of the pile covers. Most likely, previous authors on the topic simply overlooked this topic in lieu of reiterating the importance of using pile covers to preserve lumber quality and in turn lumber value.

A recommendation that was consistent across all pertinent literature reviewed is that the roofing material should extend at least six inches over the ends of the lumber packs it will be protecting. This practice is recommended to help prevent checking and splitting on the ends of the lumber by minimizing exposure to the elements. It is not advisable to have an overhang on the front side of the pile cover that would come in contact with the vertical portion of a forklift mast and likely result in unwanted movement of the top lumber courses. Literature on the topic gives mixed opinion on the need for any overhang if commercial end coatings are applied to the lumber. There are also varying opinions on the benefits of designing the pile covers with a pitch to move water away more efficiently. Readers are encouraged to delve into the list of publications that went into forming this publication to learn more about the nuances of this aspect of pile cover construction.

When the topic of pile covers is raised among sawmill owners and managers, the need to secure the pile covers to the lumber packs will always be a point of debate. A strong argument can be made that securing pile covers is a commonsense operational procedure to prevent movement and possible toppling of the pile covers onto employees or equipment. However, if the air-dry yard does not typically experience high winds or if it somehow determined that the pile covers to be used can tolerate high winds, then the additional effort needed by an employee to secure a pile cover to a lumber pack may not be warranted. Additionally, the argument can be made that even if pile covers are not used, the same operational hazard remains if the top course of lumber is not somehow secured against unwanted movement. As previously mentioned, recommendations in this publication should always be verified as consistent with state and federal occupational safety regulations before being implemented.

Figure 3. Example of tie-downs to secure pile covers in place and prevent movement. Photo source: Coos Forest Products.

The U.S. Department of Agriculture’s publication, Air Drying Lumber in a Forklift Yard (Rietz 1970), offers some other suggestions such as C-clamps for preventing high winds from overturning pile covers. The relatively simple attachment apparatus shown in Figure 3 would require some upfront work to attach the strings to the pile cover but once in place, this design would likely last for up to twelve months before the string would need to be replaced. The attachment design in Figure 3 would however require the forklift operator to leave the forklift every time a pile cover is placed in position. In general, efficient forklift operations seek to minimize the number of times the operator leaves the machine. Although it does not solve the problem of the operator having to leave the forklift cab, another option is to place additional pack bolsters or pallet cants on top of the pile covers. Ultimately the decision to secure or not secure pile covers will need to be made sawmill owners and managers.

Commonly used materials for the roof component of pile covers include: 1) lumber, 2) plastic corrugated roofing panels, 3) metal corrugated roofing panels, or 4) a combination of lumber and a moisture resistant membrane. Choosing the material to affix to the pallet cants must be carefully considered as repetitive movement of the pile covers by forklifts will eventually cause failure.

C-Clamps for High Wind Situations

The U.S. Department of Agriculture offers some other suggestions such as C-clamps for preventing high winds from overturning pile covers. The relatively simple attachment apparatus shown in Figure 3 would require some upfront work to attach the strings to the pile cover but once in place, this design would likely last for up to twelve months before the string would need to be replaced.

Figure 4. The boards missing from the pile covers in the above photograph can easily be replaced with low-grade lumber that is generated at the sawmill. Photo source: Patrick M. Rappold.

Lumber pile covers can be created by affixing uniform thickness and variable width boards to uniform sized small dimension cants. The purpose of consistent sizes and materials is to have uniform weight distribution across the stack. The pile covers illustrated in Figure 4, are neither providing uniform distribution of fully protecting the lumber piles from the elements due to missing boards. To fully realize the protection that the pile covers can provide, the boards will need to be replaced. When low-grade lumber is used, the cost to repair the damaged pile covers is minimal. Other material choices can be more costly and likely not as easy to repair. Doubling the layers and overlapping the seams can add additional protection to help prevent the pooling of water on the lumber surfaces being protected by the pile covers.

Commonly Used Materials for the Roof Components of Pile Covers

1. Lumber

2. Plastic corrugated roofing panels

3. Metal corrugated roofing panels

4. A combination of lumber and a moisture resistant membrane.

Choosing the material to affix to the pallet cants must be carefully considered as repetitive movement of the pile covers by forklifts will eventually cause failure.

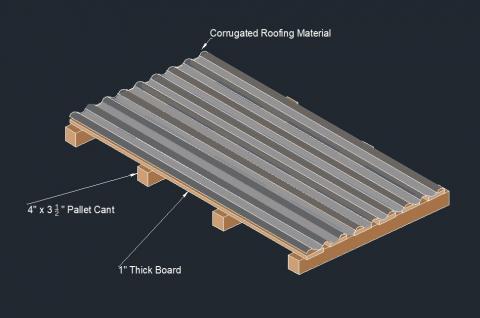

PLASTIC OR METAL CORRUGATED ROOFING PANELS

Galvanized steel or high-density plastic corrugated roofing panels are typically 26 – inches wide and precut to 6, 8, and 12– foot lengths. In terms of fabricating, the corrugated roof panels are easily attached to boards laid cross wise across pallet cants as illustrated in Figure 5. Since the corrugated roofing panels are much lighter than pieces of lumber, they are more susceptible to being moved by high winds. To add extra weight and decrease the effects of high winds, corrugated roofing panels in combination with a layer of boards can be fastened to pallet cants. While corrugated roofing panels do provide a great degree of protection from the weather, they are much more susceptible to damage by forklifts and holes are not easily repaired. Different epoxies can be used to patch small holes in metal and corrugated roofs, but the ability to repair large holes is limited and usually the entire panel needs to be replaced. However, the cost of corrugated panels can represent a significant investment for a large volume air-dry yard for a roof material that can easily be damaged when moving pile covers.

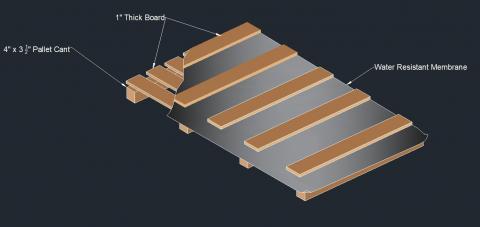

MOISTURE RESISTANT MEMBRANE BOARD ROOFS

Another option is a combination of lumber and a moisture resistant membrane “sandwiched” between two layers of boards fastened to pallet cants (Figure 6). Woven plastic lumber wrap or house wrap products that are used under the exterior siding of residential homes are both suitable materials to use. Woven plastic lumber wrap is water resistant and commonly used to protect finished softwood lumber during transport and storage. A bottom layer of boards provides a platform to affix the water-resistant membrane and protects the membrane from damage by forklifts when being placed on lumber piles. The top layer of boards not only adds weight, but it also helps protects the water-resistant membrane from being damaged if pile covers are stacked on one another when not in use. While using lumber wrap is not as cost effective as simply affixing individual boards to pallet cants, it does add an additional barrier against rain and snow melt. Pile covers that can protect lumber from moisture, reducing drying time and degrades, have been shown to recoup the associated labor and material costs in five or six uses (von Segen 1981).

“Pile covers that can protect lumber from moisture, reducing drying time and degrades, have been shown to recoup the associated labor and material costs in five or six uses (von Segen 1981).”

Figure 5. Diagram of a pile cover with a corrugated roof cover. Image source: Patrick M. Rappold.

Figure 6. Diagram of a pile cover with a water-resistant membrane sandwiched between two layers of boards. Image source: Patrick M. Rappold.

OPERATIONAL CONSIDERATIONS

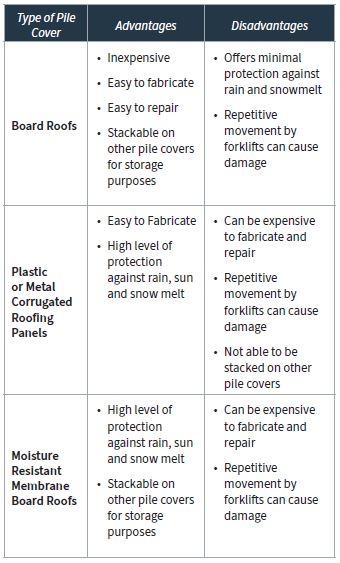

The volume and value of the lumber being air-dried should be the driving factor when deciding upon which pile cover design will be used. High-volume lumber manufacturers will need to maximize the available space in air-dry yards so pile cover designs that allow for stacking during storage should be a

main consideration. For manufacturers looking to minimize water stains in lumber, a pile cover design that offers the most protection against from rain and snow melt should be considered. Table 1 provides an overview of the advantages and disadvantages of the three pile cover designs presented in this publication.

Regardless of the pile cover design used, regular attention to the upkeep of the covers is necessary to ensure that loose boards are not compromising the integrity of the pile cover. Scheduling annual or semiannual pile cover maintenance should help to identify any issues that need to be addressed

before snow and rain negatively affects the lumber. Instructing forklift operators to consolidate pile covers that need maintenance will facilitate efficient identification of repair needs.

“Regardless of the pile cover design used, regular attention to the upkeep of the covers is necessary to ensure that loose boards are not compromising the integrity of the pile cover.”

References

Cuppett, D.G. 1966. Air-drying practices in the central Appalachians. Res. Pap. NE-56. Upper Darby, PA: U.S. Department of Agriculture, Forest Service, Northeastern Forest Experiment Station. 19 p.

Dawson-Andoh, B.E., M. Wiemann, L. Matuana, and J. Baumgras. 2004. Infrared and colorimetric characterization of discolored kiln-dried hard maple lumber Forest Prod. J. 54(1):53-57

Forest Products Laboratory. 1999. Air drying of lumber. Gen. Tech. Rep. FPL–GTR–117. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 62 p.

Kreber, B. 1994. Understanding wood discoloration helps maximize wood profits. In: Proceedings 45th Annual Meeting of the Western Dry Kiln Association. Vancouver, B.C. Western Dry Kiln Association, Corvallis, OR. pp 72-76

McMillen, J.M. and E.M. Wengert. 1977. Drying eastern hardwood lumber. U.S. Department of Agriculture. Agriculture Handbook No. 528. 104 p.

Rietz, R.C. 1970. Air drying lumber in a forklift yard. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. Madison, Wis. 23p.

Rietz, R.C. and R.H. Page. 1971. Air drying of lumber: A guide to industry practices. Agricultural Handbook No. 402. U.S. Department of Agriculture, Forest Service. 110p.

von Segen, W.W. 1981. Save money with good air-drying practices for hardwood lumber. Forestry Bulletin SA-FB/U 1. Atlanta, GA: U.S. Department of Agriculture, Forest Service, Southeastern Area. 6p.

Wagner, F.G., N.R. Smith, and A.G. McDonald. 2008. Initial high-temperature schedule to reduce drying time and control kiln brown stain in ponderosa pine shop lumber. Forest Prod. J. 58(12):29-32

Wengert, E.M. 2006. Principles and Practices of Drying Lumber. Lignomat USA Ltd. Portland, OR. 59p.

About the Authors

Patrick Rappold works for the USDA Forest Service as a Regional Wood Utilization Specialist and is stationed in Milwaukee, WI. Patrick works closely with state and forest industry partners throughout the northeast and Midwest to expand forest markets and increase manufacturing efficiencies. Patrick is also affiliated with the USDA Forest Service’s Wood Education & Resource Center in Princeton, WV.

Andrew Fast is the State Forest Industry Specialist with UNH Cooperative Extension and is based at the University of New Hampshire in Durham, NH. His primary responsibilities are to provide statewide leadership and support to the forest industry through educational programing, business attraction and retention, economic development and research.

Contact Information

Patrick Rappold | 414-477-9167 | patrick.rappold@usda.gov

Andrew Fast | 603-841-6544 | andrew.fast@unh.edu