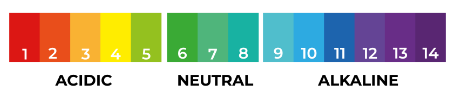

Color-coded pH scale from 1 to 14, showing from left to right, red for acids, green for neutral, and purple for bases—illustrating the spectrum from highly acidic to highly alkaline substances.

Water is the primary carrier in pesticide applications. However, the pH of spray water (a measure of how acidic or alkaline it is) can drastically impact pesticide stability, effectiveness and crop safety. Before each spray application, testing and adjusting the water pH is essential to ensure pesticide performance and protect crops, equipment and the environment.

Why Water pH Matters in Spray Mixes

Many pesticides remain stable only when mixed with slightly acidic to neutral water, typically within a pH range of 5.0 to 6.5. When pesticides are mixed with alkaline water (water with a pH above 7) they can undergo a chemical breakdown known as hydrolysis. This reaction can significantly reduce the pesticide’s effectiveness, in some cases within just a few minutes of mixing. As a result, pest control is compromised, product is wasted and costs increase due to the need for additional applications. It's important to note that with each one-unit increase in pH, the rate of hydrolysis accelerates tenfold, further emphasizing the need to monitor and adjust water pH before pesticide application.

Understanding pH and Alkaline Hydrolysis

Best Practices for Pesticide Mixing

| Insecticide | IRAC Group# | Ideal pH | Half-life at pH 9 | Notes |

|---|---|---|---|---|

| Malathion | 1B | 5.0–7.0 | < 5 minutes | Extremely unstable |

| Carbaryl (Sevin) | 1A | 6.0–7.0 | ~24 minutes | Buffer if pH > 7 |

| Imidacloprid | 4A | Stable | Stable | Less affected by pH |

This chart highlights how water pH affects the stability of certain insecticides and why it's critical to test and adjust your spray water before mixing. The “Ideal pH” column shows the range where each pesticide is most stable. When water is too alkaline (pH above 7), some insecticides like Malathion or Carbaryl can degrade rapidly through a process called alkaline hydrolysis. The “Half-life at pH 9” indicates how quickly this breakdown occurs; for example, Malathion loses half its effectiveness in less than 5 minutes at pH 9. The notes provide guidance on which products require buffering or are less affected by pH.

This chart provides only a snapshot of pH-sensitive insecticides, but many other pesticides, including herbicides, fungicides and growth regulators, can also be affected by water pH. To find pH stability information for other products, applicators should start by carefully reviewing the pesticide label and Safety Data Sheet (SDS), which may include recommended pH ranges for mixing and compatibility warnings.

How to Test Spray Water for pH

Regular pH testing is essential, especially if using water from wells, ponds or seasonally variable sources. There are two main tools for testing:

- Digital pH Meter: An electronic device that provides fast, accurate readings. It uses a glass electrode probe that must be calibrated regularly using pH buffer solutions.

- pH Test Strips: Paper strips treated with pH-sensitive dye. Simply dip the strip in water and match the resulting color to a chart. They are less precise than digital meters but are affordable and user-friendly.

Test before adding any chemicals and again after mixing, as some products can alter the final pH of the tank mix.

Image Description: Two gloved hands are shown. The left hand holds a pH color chart displaying a range of colors corresponding to pH values from 1 to 12. The right hand holds a pH test strip, which is being compared against the chart to determine the pH level.

Image Description - A person in protective clothing—white suit, yellow overalls, gloves, and a face shield—is standing in an agricultural field with rows of young plants. They are handling a green container with blue straps, appearing to pour or mix liquid pesticide into it. Image shows best pesticide handling practices.

Best Practices for Pesticide Mixing

Step 1: Test Your Water

- Use a digital pH meter (most accurate) or pH test strips.

- Test before every spray, as water pH can vary daily due to:

- Weather (rainfall, drought, sunlight)

- Source (well, pond, municipal)

- Let water run to flush out hoses before sampling.

- Test immediately after collection, as pH can change over time.

- Re-test after all products are added to the tank.

Step 2: Check Product Labels

- Follow all label instructions and Safety Data Sheets (SDS).

- Look for recommended pH ranges and mixing instructions.

- Do NOT acidify water if the label advises against it (e.g., copper fungicides).

- If no pH is listed, assume 5.5–6.5 is safe for most pesticides.

Step 3: Adjust Water pH (If needed)

- Add buffering or acidifying agents before adding pesticides.

- Examples of commercial buffers:

- Buffer P.S., Buffer Extra Strength, Brandt Indicate 5

- Aqua-Balance+, Ag-Balance+: buffer + sequesters hard water minerals.

- Flush Conditioner®: lowers pH and sequesters calcium, magnesium, iron.

- Citric Acid (granulated): A food-grade acidifier. Example: 2 oz per 100 gal typically lowers pH from ~8.3 to ~5.4 (always test to confirm).

- Many products have color indicators to visually confirm pH (e.g., pink/red = pH 5, orange = pH 6).

NOTE: Never lower pH below 5.0 unless specified on the label.

Step 4: Mix Immediately

- Add pesticides only after adjusting pH.

- Keep agitators running while adding products.

- Test final tank mix pH, especially when mixing multiple products.

- Apply within a few hours of mixing, do not let mixtures sit overnight.

Note: 50% of active ingredients can degrade if left in tank too long.

Important Cautions

- Do not lower pH when using:

- Copper-based fungicides (e.g., copper sulfate, lime sulfur)

- Phosphorous acid fungicides

- Sulfonylurea herbicides

Acidifying water with these products can lead to plant injury (phytotoxicity) or render pesticides ineffective.

Guidelines for Using Buffering Agents

Before using a buffering agent in your spray tank, it's important to perform a simple jar test. Start by adding a few drops of the buffer to 8 ounces of water and test the pH to determine how much buffer is needed. Based on the results, for every three drops of buffer required in the jar test, you should add approximately 2 ounces of buffer per 100 gallons of water in the spray tank. After adding the buffer to the tank, re-test the water to ensure the pH is within the desired range. Once the correct pH is confirmed, add the pesticides while maintaining constant agitation to keep the solution well mixed. Some commercial buffering or acidifying products include pH sensitive color indicators that change the color of the spray solution such as turning red or pink at pH 5, orange at pH 6, or yellow-green above pH 7 making it easy to visually confirm pH without repeated testing.

Image Description - Three beakers are shown, each filled with a different colored liquid. The left beaker contains a clear liquid, the middle beaker holds a yellow liquid with an electrode or sensor immersed in it, and the right beaker contains a pink liquid.

Maintaining the proper pH in your spray water is a simple yet essential step for achieving safe and effective pesticide applications. Always start by testing your water’s pH before each use, as it can vary with source and environmental conditions. If needed, adjust the pH to the recommended range using a suitable buffer or acidifier before adding any pesticides. Use buffering agents carefully and follow all label directions to avoid overcorrection, which could harm crops or reduce product efficacy. Once the pH is correct, mix and apply the solution promptly—never leave mixtures sitting overnight. Equally important is keeping clear records of pH readings, products used, and any adjustments made. By consistently following these steps and referring to pesticide labels and Safety Data Sheets (SDS) for guidance, you’ll help ensure product performance, protect your crops and equipment, and make more cost-effective, environmentally responsible applications.

Online Resources

Visit the US EPA website and read "What is pH?"

University IPM Resources:

Visit the Michigan State University Extension website and read "Effect of water pH on the stability of pesticides"

Visit Penn State Extension website and read "A Water Quality Toolkit for Greenhouse and Nursery Production"

Visit UMass Extension website and read "Effects of pH on Pesticides and Growth Regulators"

November 2025

Extension Services & Tools That Help NH Farmers Grow

Newsletters: Choose from our many newsletters for production agriculture

Receive Pest Text Alerts - Text UNHIPM to (866) 645-7010