Most farms will eventually have a construction project to add new facilities or improve existing ones. Depending upon the skill of the owner and scope of the project, these may be done on the farm with or without the help of a contractor.

The first step is to check with local town or city officials to see if there are requirements for building permits, zoning restrictions or set-backs from property lines, water bodies, or adjacent wetlands. Building codes will especially have standards for foundations and roof snow loads. It’s good to start off right with these officials and perhaps even get some good input for your project. If you are the builder, you take on the role of organizing the project and often serve as a general contractor, arranging other services such as excavation, concrete pouring, etc., to get the job done.

Lean-tos can be a low-cost solution to adding space, but may have limited access and compromise the existing structure.

In New England, selecting a site for a building project can be a challenge. A lot of farm buildings were built on the worst land so as not to use up good cropland. When these old buildings were added onto, it often perpetuated poor location issues. Be sure to consider such things as accdess, drainage, topography, and environmental concerns.

The temptation is to choose a site and immediately start building. The problem with this is that the existing topsoil won’t drain adequately and water will flow into the building from roof rainwater and surface run-off. Spend time removing the topsoil and adding a gravel base larger than the building to promote flow away from the structure.

Before building any structures, the first step is to check with local town or city officials to see if there are requirements for building permits, zoning restrictions or set-backs from property lines, water bodies, or adjacent wetlands.

If adding a lean-to onto a building, make sure the side wall is high enough for the addition to maintain the slope of the existing roof and still have adequate height at the eaves for air flow and equipment passage.

Site

In New England, selecting a site for a building project can be a challenge. A lot of farm buildings were built on the worst land so as not to use up good cropland. When these old buildings were added onto, it often perpetuated poor location issues.

Here are a few factors to consider when determining the site of a new

building:

- Access

- Topography

- Orientation to the sun and prevailing winds

- Drainage

- Area needed plus room for future expansion

- Environmental concerns

- Distance from other buildings

- Soil type

- Utilities

The temptation is to choose a site and immediately start building. The problem with this is that the existing topsoil won't drain adequately and water will flow into the building from roof rainwater and surface run-off. Spend time removing the topsoil and adding a gravel base larger than the building to promote flow away from the structure. Follow these steps:

1. Remove topsoil

2. Add a raised gravel base larger than the building

3. Provide access roads

4. Install needed drainage systems

5. Lay conduits for running underground electrical wiring and plumbing

Foundation

The foundation will establish the dimensions and squareness of the building. Any inaccuracies will follow you throughout the project. Foundation options are:

- Concrete foundation

- Pressure-treated posts

- Pre-cast or poured post bases

- Concrete slab

In New England, a concrete footing with a four-foot frost wall is a common practice. The footing is poured first and is larger than the thickness of the wall. Vertical reinforcing rods placed in the footing tie the wall-pour to the base. There are post brackets which can be embedded into fresh concrete and make a rugged mounting for a post on a wall. This can eliminate the need of burying a post in the ground and provide durable side-walls for scraping against.

With post construction, you can bury the posts to a depth of four feet, or use pre-cast concrete bases or concrete tubes at the base of each post. There is a growing concern about how well the wood preservative treatment penetrates large-dimension posts, so laminating smaller stock, which has deeper penetration, may help ensure a longer lifespan of the building. In many instances, the frost wall may be a better option, and it provides rugged side-walls for containing bedded-packs or scraping manure.

A concrete pad can also be used as a base for a building. These are often built after the pattern of an “Alaskan Slab,” with thicker concrete poured around the edges and perhaps some rigid foam insulation along the sides to prevent heaving.

Building Construction

There are several building options for a barn. These include:

- Conventional stick framing

- Post-frame

- Hoop structure

- Greenhouserse

The traditional method of construction in the mid to late 20th century was “stick built”. This uses 2 x 4 or 2 x 6 framing material attached to an upper and lower plate and fastened to a floor deck built on a concrete wall.

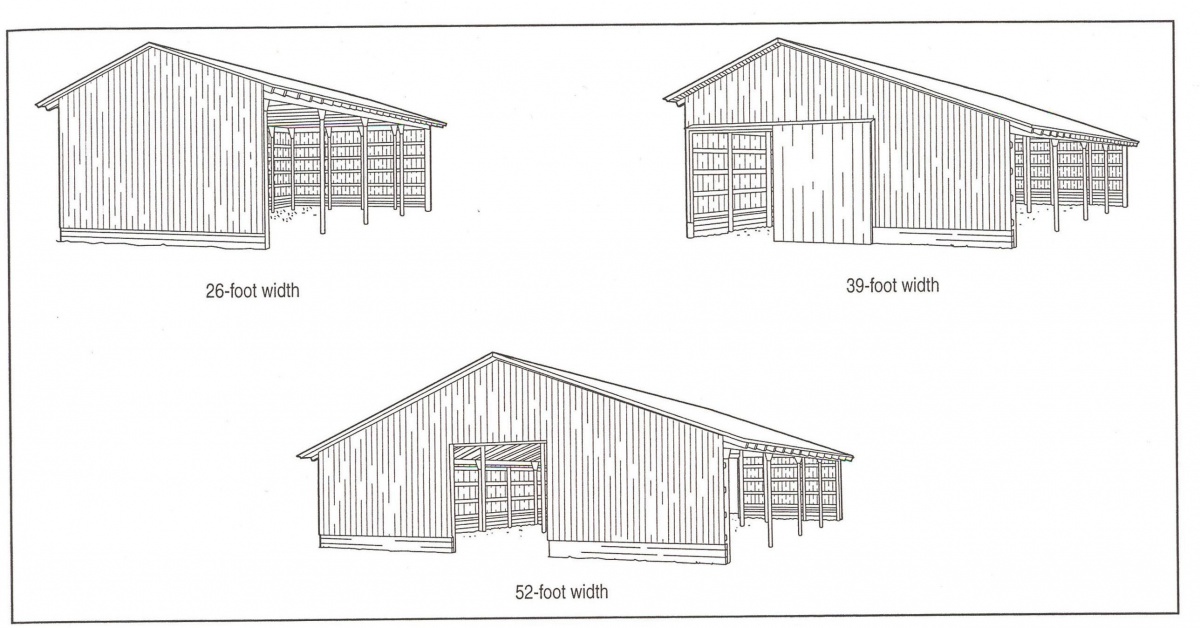

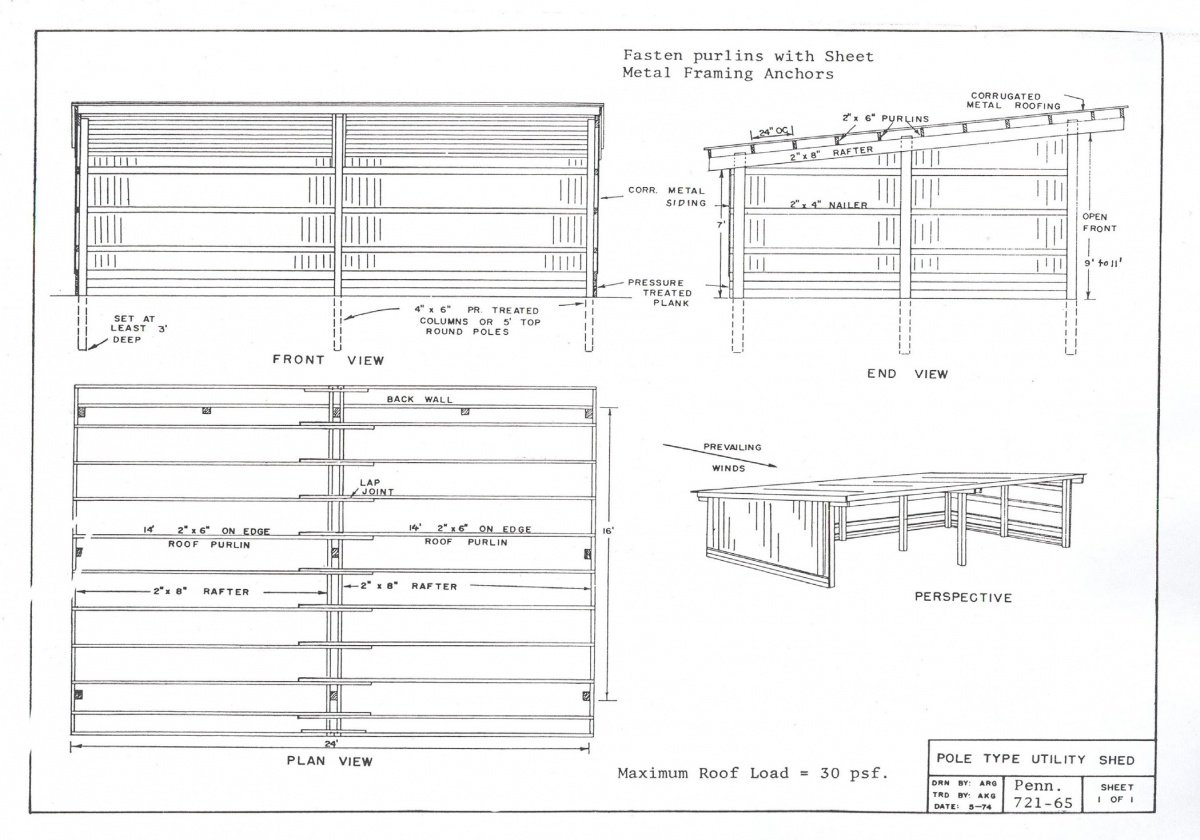

Many farm buildings have high sides, open fronts and several large doors and are more rugged and easier to build as pole buildings. Very little concrete needs to be poured and native lumber can be used for vertical siding.

A pole building has the posts either in the ground or sitting on a support and posts are often 8’-12’ apart. They are held together with a plate on top that supports the roof structure and horizontal nailing girts along the side for attaching the siding.

Other options for farm buildings include vinyl-fabric hoop structures and greenhouses. These have the advantage of letting in some solar radiation, and they can be disassembled and moved when no longer needed. Depending upon their size, these structures may be built on pipe supports, wooden sidewalls or concrete foundations. The disadvantage is that the roof covering has a shorter lifespan than traditional coverings, and animals may chew on the fabric if it is within reach.

Fasteners

Proper fasteners need to be selected for the job. Generally nails, bolts, and lag bolts are used in farm construction. Galvanized nails will prevent rusting stains on siding and will last longer. Pole barn structures require the special ring nails that anchor tightly. It is important to select fasteners that are rated for pressure-treated wood when using that material, because the chemicals can react with the fastener and cause a failure.

Phillips head screws can be used for wood construction. Square-drive heads or star-heads may be preferable in applications where things may have to be removed, as the drive bits fits more securely and the screws come out easier.

Roofing

Roofing choices may be somewhat determined by the style of construction and intended use of the building. The roofing choices are:

A. Wood surface with tab shingles or non-tabbed architectural shingles

B. Metal roofing (painted or coated steel)

C. Aluminum roofing

Traditional “stick-built” structures often have a plywood roof covered by tab shingles or the non-tab, architectural shingles.

Trusses are often used on pole buildings. These are pre-engineered roof members with internal braces, which allow a clear-span building without internal posts. We recommend buying pre-built units, as the engineering is critical to their strength. Proper cross-bracing to tie the trusses together is critical, so follow manufacturer’s specifications. Purlins are 2 x 4s spaced apart and nailed to the top of the trusses for supporting the roofing material. Metal (painted or coated steel) roofing can be used if the building is well ventilated or aluminum should be used if there is containment of corrosive gases given off by animal manures. Whenever possible, avoid building a second floor, but add more bays to gain space. This avoids the superstructure needed to support the floor, and it eliminates a possible cave-in to the first floor in case of a fire.

DID YOU KNOW?

Roofing choices may be somewhat determined by the style of construction and intended use of the building.

Other Considerations

Agricultural buildings should always be designed with animal, equipment, and human “traffic flow” in mind. Animals must move in obvious straight directions. Equipment needs to be maneuvered easily for mechanical cleaning and feeding. Doors need to be wide enough to accommodate equipment, and eaves have to be high enough to allow the passage of tractors with cabs.

Often people design barns for human comfort, but it is important to meet the needs of the animals. Decide early on whether the barn is going to be closed up and insulated and ventilated, or kept open and cold with natural ventilation. Cold barns with natural air and open to the south sun, provide very healthy environments. Sidewall curtains made of fabric (canvas or inflatable plastic tubes) can be used in place of wood sheathing and raised or lowered for ventilation.

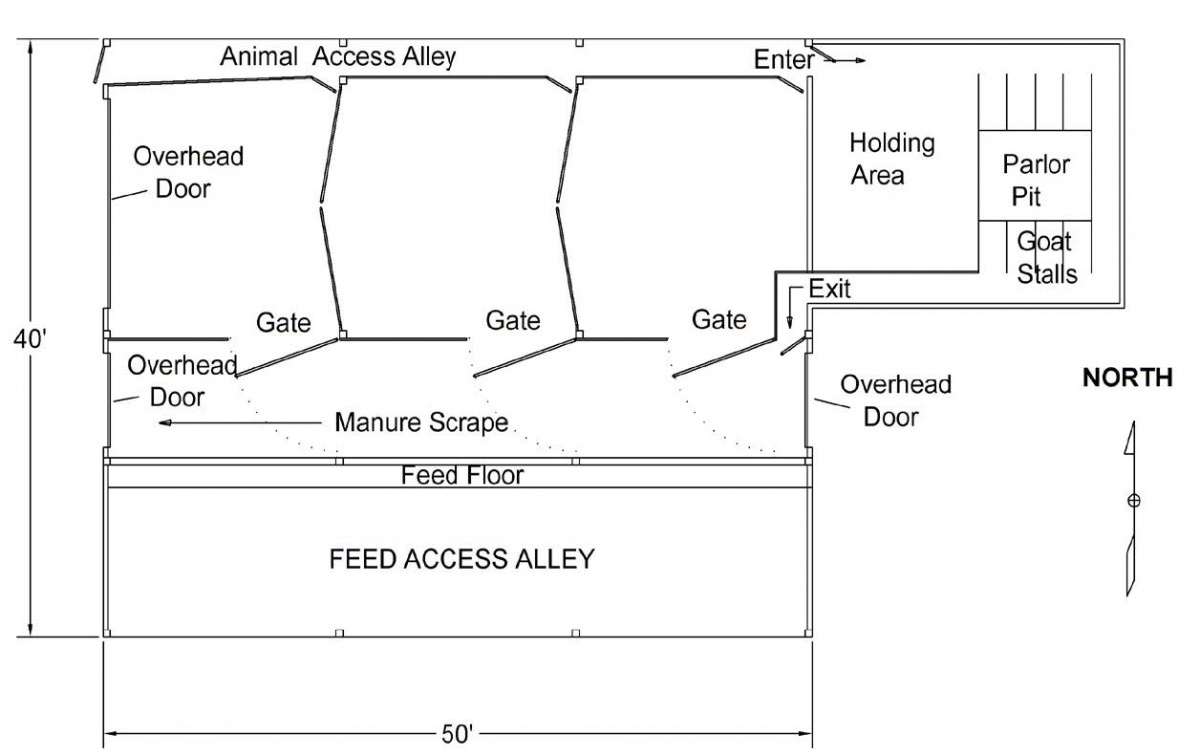

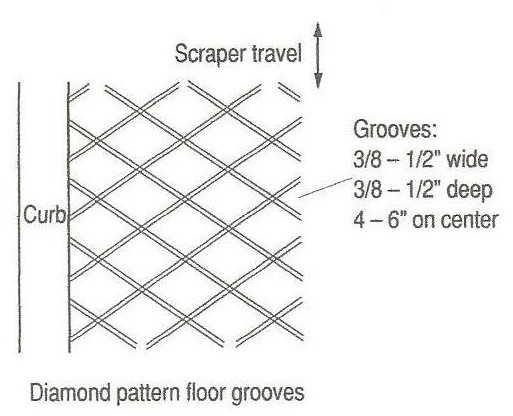

Another feature that can be built into animal facilities is a people and/or animal access alley. This adds a little expense, but can be built along the back wall of a barn to make it easier to check animals or move them from pen to pen without disturbing the other animals.With animal housing, it is important not to make the concrete floors too smooth. There should be a minimum of a broom finish, and if there is a lot of animal traffic and scraping activity, the floor needs to be grooved. It is often preferable to pour the floor and come back later with a commercial grooving machine and use a diamond pattern. Trying to groove at the time of pouring concrete can leave a rough surface because the concrete cures faster than it can be worked.

Regardless of the type of facility and design, build it with flexibility in mind and with an eye to other future uses. See figures 1 and 2 for pole barn examples.

Handy Facts for Construction - Calculations

Area:

Rectangle = L (Length) x W (Width)

Triangle = B (Base)/ 2 x H (Height)

Circle = 3.14 (π) x R2 (Radius)

Total Board Feet = No. of pieces x T (Thickness in inches) x W (Width in inches) x L (Length in feet)

Volume:

Cube = L (Length) x W (Width) x H (Height)

Cylinder = 3.14 (π) x R2 (Radius) x H (Height)

Cone = 3.14 (π)/ 3 x R2 (Radius) x H (Height)

Measurements:

Cubic Yard = 27 Cubic Feet

Board Foot = 144 Square Inches

Acre = 43,560 Square Feet

Bushel = 1.2445 Cubic Feetcrete slab

Weights:

Water 8.3 lbs/gallon

Grain 40-45 lbs/cubic foot

Hay (baled) 15-20 lbs/cubic foot

Sawdust 12 lbs/cubic foot

Concrete 150 lbs/cubic foot

Concrete - Some Basic Numbers:

Water: 62 Pounds per Cubic Foot

Water: 7.5 Gallons per Cubic Foot

Portland Cement: 94 Pounds per Cubic Foot

Sand/Gravel Concrete: 112 Pounds per Cubic Foot

Gravel Concrete: 148 Pounds per Cubic Foot

Cement/Water Ratio: of 0.50 Means About 1 Volume of Water Per 3 1/2 Volume of Mix

Concrete Strength: Tensile Strength About 1/8 of Compression Strength

One "Yard" = One Cubic Yard = 1 Yard x 1 Yard x 1 Yard

= 3 Feet x 3 Feet x 3 Feet = 27 Cubic Feet

= 36 Inches x 36 Inches x 36 Inches = 46,656 Cubic Inchesre.

Concrete needed for a dairy barn alley floor that is 5 inches thick and 12 feet wide and 100 feet long =

5/12 x 12 x 100 = 500 cubic feet = 500/27 = 18.5 cubic yards.

Download the Resource for the complete printable factsheet