Emergency Erosion Control Techniques for Dealing with Severe Weather Conditions During an Active Timber Harvest

A field note is a report from "the field," based on observation and experience. The techniques and suggestions included were developed in conversation with practitioners and during a series of in-the-field workshops. This project is a collaboration between UNH Cooperative Extension, the N.H. Division of Forests and Lands, N.H. Timberland Owners Association and New Hampshire loggers, landowners and foresters. It was partially funded by the U.S. Forest Service Landscape Scale Restoration grant.

by Karen Bennett and Jim Frohn, UNH Cooperative Extension

Contributors include:

- Ray Berthiaume, Wagner Forest Management

- Bryan Comeau, Dalton Mountain Forestry, LLC

- Steve Gaines, N.H. Timberland Owners Association

- Ryan Harvey, Consulting Forester

- Dennis McKenney, New England Forestry Consultants

- N.H. Division of Forests & Lands

- Steve Patten, Pine Tree Lumber, Inc. & N.H. Timberland Owners Association

- Logan Sears, Long View Forest Contracting

- Sarah Smith, UNH Cooperative Extension, emeritus

- Nate Taylor, Long View Forest Contracting

Background

This project—to harness and share in-the-woods experience of loggers, foresters and landowners who respond to severe weather events during timber harvest—was the brainchild of Sarah Smith, Forest Industry Specialist, emeritus. We suggest useful, practical and cost-effective techniques to use when an unexpected and sudden change in the weather results in changes to ground conditions during an active logging job.

The techniques and suggestions included were developed in conversation with practitioners and during a series of in-the-field workshops. This project is a collaboration between UNH Cooperative Extension, N.H. Timberland Owners Association and New Hampshire loggers, landowners and foresters. It was partially funded by the U.S. Forest Service Landscape Scale Restoration grant.

Introduction

Best Management Practices (BMPs) for erosion control are tried and true techniques used to minimize the effects of logging on water quality. BMPs are effective when planned ahead of the timber harvest and installed correctly. Long-term effectiveness depends on vigilant inspection and adequate maintenance of installations. The goal of BMPs is to protect water quality. The technique used is not as important as how effective it is.

techniques used to minimize the effects of logging on water quality. BMPs are effective when planned ahead of the timber harvest and installed correctly. Long-term effectiveness depends on vigilant inspection and adequate maintenance of installations. The goal of BMPs is to protect water quality. The technique used is not as important as how effective it is.

When used in “normal” circumstances, “standard” BMPs are effective. A 2016 evaluation of New Hampshire timber harvest showed BMPs resulted in stable soil at stream crossings 82 percent of the time. (A 2005 evaluation found that soil was stable 77 percent of the time at stream crossings).

Recent research from the University of Wisconsin documented a 2- to 3-week shortening of frozen ground conditions from 1948 to 2012 thus shortening the winter logging season (see Changes in winter conditions impact on forest management in north temperate forests by Chadwick Rittenhouse and Adena Rissman in Journal of Environmental Management,149 (2015) 157–167). Loggers, foresters and others responsible for implementing BMPs on timber harvests notice increasingly unpredictable and severe weather events—heavy rains, open and snowless winters, frequent thawing and freezing. When these “extreme” weather events occur during a timber harvest, the water and changing ground conditions can overwhelm the standard BMPs. Ingenuity and action are called for.

These suggested techniques aren’t intended to replace the New Hampshire Best Management Practices for Erosion Control on Timber Harvesting Operations; rather they are designed to augment them with ideas and techniques that can be used short-term, in an emergency—as when a heavy rainfall is expected before a timber sale is properly closed-out or an unexpected winter thaw occurs, or some other unexpected ground condition is encountered.

The techniques are for use before close-out—for when the weather has turned during an active logging job. (Close-out meaning the logger or land manager has finished the timber harvest and is removing temporary bridges, culverts and fords). Close-out also involves grading slopes for stabilization, installing permanent water diversions—like water bars or ditches—as well as seeding (if appropriate) to stabilize soil. A winter timber sale is often closed out after mud season. Equipment is generally removed from the site when spring break-up occurs and a smaller selection of equipment returns to finish the work or to close-out the job.

Planning

Planning isn’t just about job-layout. It’s about anticipating weather happening—though we don’t’ know when or how it will happen. Think about how you can react when unplanned weather occurs. For example, by stockpiling brush instead of chipping it all or having timber mats on-hand, you will be ready for soft spots developing in skid trails during a thaw or downpour. Asking a few simple questions during the timber sale layout will help anticipate potential problems and help plan for preventing them.

Where will the water come from and where will it go?

The answer may seem obvious but natural and man-made dips and bumps may send water in curious directions. Land managers often check roads before storm events to monitor their status. Maps can help but on-the-ground reconnaissance is far more important to head off problems. It is important to spend time looking at the property, perhaps during a heavy rain, to see what is happening with water flow. A keener understanding of the water flow and direction can prevent a heavy rain from transporting sediment to streams or other water bodies as well as causing damage to roads.

What will that frozen ground do with an unplanned thaw?

Harvesting on frozen or snow-laden ground is an effective BMP to minimize rutting, erosion and sedimentation. However, just because it’s a winter job doesn’t mean you don’t have to think about erosion and rutting. One response to an unplanned thaw is to leave, but a lot can happen if you leave the job before close-out.

Tools, Equipment and How-To

Many of the suggested techniques are simple installations using hand tools—shovels, pick axes or hoes—while others require standard onsite logging equipment. The techniques, tools and equipment used depend on the ground conditions encountered. The descriptions and illustrations provided should give loggers, foresters and landowners the direction needed to install the suggested practices. Instead of detailed installation instructions (which are beyond the scope of our project), we rely on the “Yankee ingenuity” of our readers to choose the right practice, in the right circumstance and to install it in the right way.

Using water-diverters on frozen roads and trails with a slope

Log-barrier water-diverter

Water bars can’t be properly installed when the ground is frozen solid. This is where planning ahead can be useful. An option is to install reinforced waterbars before the ground freezes. A log-barrier water bar is perhaps the simplest and most effective water-diverter when the ground is frozen. The log is placed at 30-degrees to the direction of the road or trail. Slash and other loose material is placed against the uphill side to serve as a filter for water flowing down the road. This technique is for short-term use when a proper water bar cannot be used because the ground is frozen or ledge prevents digging.

Log used to divert water in a skid trail on frozen ground

Snow and ice water-diverter (not illustrated)

Snow and ice can be used effectively to divert water. Loggers often push a trail of snow across the road to divert water. This technique is used when the snow and ice is starting to break up and water is moving across the surface. A skidder or other bladed machine can be used to create an ice and snow berm to prevent the water from moving.

Slash water-diverter (not illustrated)

When the ground is frozen and the water is beginning to run on the road a line of slash placed across the road at a 30-degree angle may be just enough to divert or slow the water down so it doesn’t create erosion as the road thaws. The slash should be a mix of fine and course material and tamped down to stay in place. The material may freeze in place which will make it more effective.

Straw wattle water-diverter

A straw wattle is a cylinder of compressed straw fibers wrapped in tubular woven jute-netting. Install at a 30-degree angle, secure in place and remove after the season thaw and when you can install a proper water-bar.

Straw wattle placed on frozen ground at a 30-degree angle

Close-up of straw wattle install on frozen ground secured in place.

Compost sock water-diverter

Similar to a straw wattle, a compost sock is filled with compost. Install at a 30-degree angle, secure in place and remove after the season thaw and when you can install a proper water-bar.

Compost sock placed on frozen ground at a 30-degree angle

Salt and sand to melt soil for water bar installation

Standard road salt can be placed on a skid trail or road at a 30-degree angle to melt soil ice, so the soil can be dug and a water bar installed.

Salt placed on a woods road. Showing melt in advance of placement of water bar.

Silt-fence

Temporarily secured in place with sand or onsite soil and remove after season thaw and when you can install a proper water-bar

Installation of a silt fence with sand

An interesting use of rope!

Heavy-duty rope laid on top of frozen ground acts as an impromptu water-diverter

Stabilizing soils on slopes with hay rolls and bales and wood chips and slash (not illustrated)

Using a large hay roll can stabilize soil for short-term use. Placing the roll and unrolling it across the area can work well to keep soil from moving. Moving and placing the roll may be a challenge if large equipment is not available. Bales can also be used. Onsite wood chips and slash can be placed on slopes and disturbed soils to prevent erosion.

Catching sediment

Brush and treetops

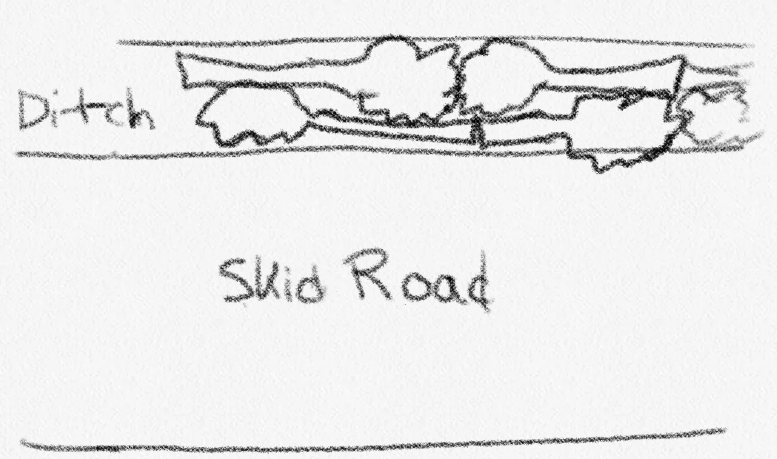

Densely packed branches, tree tops, logs and trees can be placed temporarily where excessive and unplanned water flows. For example, in a ditch alongside a skid trail or road, where a silt fence is inadequate, placing hitches of whole trees top-to-top and butt-to-butt slows water and traps sediment.

Dubbed “hitches in ditches,” the illustration shows whole trees placed in the ditch, top-to-top then butt-to-butt, so that the whole length of the ditch is lined with tops without gaps in between. At the end of the harvest, the trees are removed and processed.

Illustrating “hitches in ditches”

Ditches with sediment-free water flowing after the trees were removed and processed

Preventing rutting and compaction

Brush mats

Tree tops and small trees placed in wet and heavily used areas using mateial onsite.

Tree tops and small trees placed in wet and heavily used areas using material onsite.

Corduroy

Small logs, poles or tree tops placed perpendicular to travel in wet areas—without a defined stream channel—can be left in place after the harvest.

Corduroy on a wet section of a skid trail

Timber mats

Preconstructed mats are reusable and used to support heavy equipment in wet and heavily used areas.

Preconstructed timber mats placed in a wet area and high traffic zone to the left of the log pile

Case Studies—Using BMPs to minimize erosion

Two timber harvests are featured to illustrate how severe weather conditions changed the planned operation and how BMPs were used to stabilize soil and minimize erosion.

Dorchester New Hampshire Harvest

The Dorchester timber harvest covers 80 acres, with 50 acres and 580  cord-equivalents harvested during the first winter. The remainder of the sale will be cut the following winter. The harvest area contained one large brook and many small streams. Soils were moderately well-drained to somewhat poorly drained, which required frozen, snow-covered conditions to operate. Old skid trails provided access to the parcel.

cord-equivalents harvested during the first winter. The remainder of the sale will be cut the following winter. The harvest area contained one large brook and many small streams. Soils were moderately well-drained to somewhat poorly drained, which required frozen, snow-covered conditions to operate. Old skid trails provided access to the parcel.

The job was harvested with mechanized cut-to-length equipment—a harvester and a forwarder.

BMPs used

Two bridge panels were installed on the large stream to facilitate crossing by the forwarder. Logs were placed parallel and adjacent to the banks on each side to serve as abutments.

The small streams were crossed using pole fords. These were put in place by the harvester cutting nearby trees and placing them in the stream ahead of the machine. Additional wood was added by the forwarder, as needed. Branches and unmerchantable stems were placed in the trail ahead of the harvester to provide a mat for the machinery to travel on, and wet areas were reinforced with additional brush installed with the forwarder.

Less obvious BMPs (and ones not so easily illustrated) are in the category of decisions by the logger in response to changing ground conditions. These decisions included:

- Choosing not to use some old skid trails that were too wet or too rutted.

- Choosing not to use an old stream crossing that had wet ground on the approaches—instead using a better location downstream even though it extended the forwarding distance. This decision eliminated the chance of rutting, compaction, and sedimentation at the poorer location.

- Shutting down during the thaw when conditions were too soft to operate, regardless of the BMP installation.

- Continuously reinforcing brush mat in areas that needed it.

- Avoiding old trails in poor condition; avoiding old stream crossing with long, shallow approaches.

- Forwarding wood at night or early mornings during frozen conditions.

- Temporary shutdowns when conditions were not conducive to operating.

The contractor plans to finish the job the following winter. At the end of the first winter, pole crossings and the bridge were removed in order to allow water to flow freely. The pole material was left on site, to be placed back in the stream channel prior to operating. Bridge panels will be re-installed.

Bridge panels installed across stream. Located at narrow section with short span. Installed log headers on each bank to help extend length.

Bridge panels removed to allow for free streamflow. Left on site for return next season.

Pole fords placed in narrow streams

Pole ford removed at the end of winter to allow for spring runoff. Material left onsite for use upon return the following winter.

Heavy brush on skid trail; continuously reinforced brush mat in areas that needed it. Brush mat was laid down with processor placing limbs and tops of trees in front of the machine.

Old skid trail at stream crossing in poor condition not used in this harvest

Errol New Hampshire Harvest

The Errol location covers 289 acres and 2,870 cord-equivalents  were cut. The area was harvested in two entries—to account for excessively wet fall conditions (and deer season). The first entry was in the summer-fall, covering 91 acres and generating 800 cords of pulpwood and 60 thousand board feet of logs. The second entry was in the winter, and it covered 198 acres—1700 cords of pulpwood and 125 thousand board feet of logs were harvested.

were cut. The area was harvested in two entries—to account for excessively wet fall conditions (and deer season). The first entry was in the summer-fall, covering 91 acres and generating 800 cords of pulpwood and 60 thousand board feet of logs. The second entry was in the winter, and it covered 198 acres—1700 cords of pulpwood and 125 thousand board feet of logs were harvested.

The job was harvested with a whole-tree harvest system—feller-buncher and grapple skidder.

The logging operation used an old truck road for the main skid trail, and crossed a sizeable stream. The old truck road had a ditch running parallel to it, with cross drain culverts draining the ditch toward a brook.

BMPs used

A pre-fabricated, 35-foot, steel portable bridge was used at two stream-crossing locations—for safety reasons, a summer-fall and a winter crossing were used. The summer-fall bridge crossing was at a narrow span of the stream. Though the crossing was narrow, the banks were steep and high enough above the stream to create a safety hazard for skidders crossing a snow- and ice-covered bridge in the winter.

A second location, slightly downstream, was chosen for the winter crossing. This location had been crossed by skidders in the past. The stream was broader and shallower at this location and the bridge wasn’t long enough to span the brook. The bank on one side of the stream was low, broad, and wet, creating potential for rutting and sedimentation—confirming the need to use this crossing only during frozen conditions.

The crossing at the winter location consisted of the pre-fab bridge, which was removed from the summer-fall crossing location, plus two culverts. Timbers were placed parallel to the stream banks and the bridge panels were rolled out across the stream until each end of the panels was resting on the logs. To make up for the shortfall between the end of the bridge and firm ground, two metal culverts were placed parallel to the stream bank. Logs were placed over these and snow packed around them to prevent the culverts from being crushed. The entire installation was done during snow-covered ground, and no machinery ever entered the stream itself. The installation was removed after the harvest was completed.

The ditch parallel to the skid trail was a problem during the fall harvest. Despite staying out of the ditch itself with machinery and hitches of wood, sediment was getting into the water in the ditch and eventually in the brook. The solution was to line the ditch with whole trees, end to end—tops touching tops and butts touching butts. This effectively caught the sediment and cleared up the runoff. All the trees were removed from the ditch at the end of the job, cut into products and sold.

Illustrating “hitches in ditches"

Ditches with sediment-free water flowing after the trees were removed and processed.

Winter stream crossing location with low, broad approaches and wet soil necessitating use during frozen conditions.

Logs placed parallel to the streambanks for bridge panels to be rolled onto.

Culverts in place parallel to the stream channel and bridge panel being placed.

Bridge panel being placed and equipment remains out of the stream channel.

In-stream view.

In-skid trail view.

Related Resource(s)