Food Safety training on a produce farm involves training employees on personal health and hygiene practices as well as on-the-job specific tasks that protect food against contamination.

Health and Hygiene Practices & Training Resources

Why Wash Your Hands?

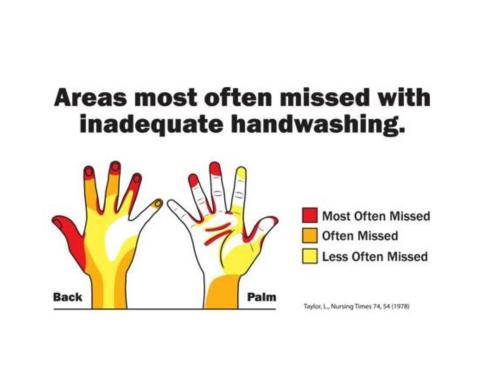

Training employees on how to effectively wash their hands may be the single most important food safety investment you make on your farm. Hands can pass spoilage and illness-causing microorganisms on to produce and surfaces touching produce. Download this picture (.pdf) and use it during training to highlight the areas most often missed when washing hands.

Graphic showing the areas most often missed when washing hands are the thumb, tops of the fingers and middle of palm.

When to Wash Your Hands?

Employees should be able to explain to you (or anyone) when they need to wash their hands. Here is a list of handwashing times to discuss with employees.

- Before handling the harvestable portion of the crop

- Before touching equipment and tools used on the harvestable portion of a crop (example: harvest containers, pack table)

- After using the restroom or taking a break (food or smoking/vaping)

- After handling animals or animal waste

- AND any other time hands may become contaminated before handling produce. See what your employees can add to the list.

Poster – Handwashing Steps

Download this poster (.pdf) and use it to teach the basic handwashing steps. Place it by handwashing stations so that employees remember how to wash their hands.

How To Wash Your Hands

- Wet Hands and Apply Soap

- Rub Hands Palm to Palm

- Lather the Backs of your Hands

- Scrub Between Your Fingers

- Rub the Backs of Fingers on the Opposing Palms

- Clean Thumbs

- Rinse Hands

- Dry With a Single Use Towel

What about hand sanitizer?

Hand sanitizer can be used after handwashing with soap and water, but not as a replacement for handwashing. When hands are dirty, hand sanitizer is not effective at killing the microorganisms that cause food-borne illness.

DIY Handwashing Stations

See examples of low-cost, portable DIY handwashing stations that can be set up in the field or wash pack area. Download these instructions to make your own. Regardless of the design of your handwashing sink or station, it should have:

- A clean, enclosed container to hold water.

- Hand soap (can be liquid or bar).

- A container to catch the used water.

- Single-use towels for drying hands or automatic dryer.

- Trash container.

Water used for handwashing should be safe to use (no detectable generic E. coli). The waste water should be disposed of away from foot traffic, the growing field, pack areas, and open water sources (stream or pond).

Gloves are not required, but if your employees use either single use or washable gloves, they need to be trained on how to maintain them in a sanitary condition and when to replace them. Employees working with produce should always wash their hands prior to putting on gloves. Employees should avoid eating and using the toilet while wearing gloves.

Single Use Disposable Gloves: Employees should replace gloves when they become damaged, torn, or contaminated. Single Use Disposable Gloves should not be used for handling chemicals or other hazardous materials. Use chemical-resistant gloves for this work to protect workers from hazardous exposure to chemical substances such as sanitizers and pesticides.

Washable Gloves: Employees may use washable gloves to protect their hands when harvesting or packing. Have a clear plan for how these gloves are handled when employees use the toilets, take breaks, and at the end of use. Make and discuss a plan for when and how often the gloves will be washed and replaced, where gloves will be stored when not in use, and where dirty gloves will be collected for washing.

Where should toilets be located?

Train employees on restroom locations on your farm and ensure employees agree with you on how to use the toilets (place toilet paper in the toilet and not in a nearby garbage bin), and they should know to wash their hands directly after using the toilet.

Toilet facilities should be accessible to both field and pack area employees. You want your employees to use toilets and wash their hands if they are handling your produce. A benchmark for distance from the field are the federal field sanitation guidelines for agriculture, which state a toilet should be within one-quarter-mile walk of field work.

Regular Cleaning: Employee hands, clothes, and footwear can become contaminated when using unclean toilet and handwashing facilities. Schedule regular cleaning times and adjust frequency if needed (this may include working with rental portable unit companies).

Reporting Problems with Facilities: Train employees to either replenish toilet and handwashing units or let them know who to report missing (or broken) items to. Handwashing units should have soap and single-use drying towels (paper or towel) and toilets should have toilet paper.

When making a visitor policy and signs for your farm, you should consider the following:

- Who is a visitor? Draft rules based on visitor determination (see Visitor Signs and Policies for examples).

- What sort of signage do I need to support my visitor policy? Should I post the rules on our website?

- What does my insurance plan require in relation to visitor policies?

- Many farms include their Visitor Policy in their Farm Food Safety Plans.

- Some farms require a check-in log for all visitors, some for recurring visitors (volunteers or contractors) and some do not require it at all.

Here are some examples of Visitor Signs and Policies for farms with and without U-pick operations.

Train employees on symptoms of health conditions that may lead to contamination of food contact surfaces or produce. For example:

- Vomiting

- Diarrhea

- Fever

- Jaundice – the yellowing of skin or eyes (symptom of Hepatitis A virus)

- Open sores

Train employees on who to report these conditions to, and ensure that this person is trained to make decisions about appropriate work options. Train employees on where to receive or access first aid on the farm.

Have a policy relating to these conditions so that you provide clear information to your employees on when they should stay home, when they can be moved to another task, or when they can continue with a normal task with a simple fix (bandage on a cut finger).

Train employees on policies that ensure that clothes, footwear, and jewelry do not contaminate produce. Here is an example policy:

- Employees must wear clean clothes daily and closed-toed shoes.

- Remove hand jewelry (if touching produce and it can’t be cleaned or sanitized).

- Hang aprons on the hooks in the wash pack room entrance area when using the toilet, going on a break, or at the end of the day. Wash the apron by rinsing with hose, scrubbing with soap in cleaning bin, rinsing with hose, and air drying it on a hook). Note: Cloth aprons should be treated the same way as reusable gloves.

- Employees who take care of the chickens cannot enter the wash pack shed with the clothes and footwear used for egg collection, chicken feeding, and mobile poultry house management.

Create a policy for your farm and use it to train your employees.

Train employees on where and when they can eat, drink, or smoke on your farm and that they should wash their hands before returning to work. A designated break area may be inside or outside but must be away from the crops in the field or away from the wash/pack activities to prevent contamination.

Here is an example policy:

Field: During designated break times, employees can eat and drink outside of the crop growing area. When harvesting and working in the field (weeding, etc.) employees can have a designated drink by their side.

Wash/Pack/Retail: During designated break times, employees can eat and drink at the outside picnic tables or in the designated break area in the covered pack shed.

What Does Job-specific Food Safety Training Include?

As part of carrying out typical production tasks, a farm needs to train its employees on activities and conditions that reduce the risk of contaminating produce. These practices are referred to as good agricultural practices. Developing good agricultural practices in the areas listed below and then training employees on them is a critical part of a comprehensive employee food safety training program.

Employee Hygiene and Health Practices

See Section covering Recommended Health and Hygiene Practices and Resources

Safe Harvesting Procedures

Train employees:

- To recognizing un-harvestable produce.

- To inspect harvest containers.

- On your farm’s protocol for dealing with broken or unclean harvest equipment.

Safe Post-Harvest Handling Procedures

This includes training employees on washing, packing, and storage procedures that ensures that produce is not contaminated. For example, what is your farm’s procedure for managing an ice scoop in between uses?

Sanitation and Maintenance Procedures

Train employees on the sanitation procedures for cleaning equipment, buildings, tools, and containers.

Risks Associated with Domesticated Animals & Wildlife

Train employees on the risks of microbial contamination caused by wildlife or by working animals and how to avoid this contamination either in the growing field and/or in the wash pack area.

Planting Medium (Substrate, Compost, and Soil) Safety

Train employees on how to ensure the planting medium does not become a source of contamination. For example, what is your farm’s policy for applying raw manure to the field or what procedures should an employee use to manage a compost pile that will be used on the field?

Pre-Harvest and Post-Harvest Water Management

Train employees on water use and application.

Employee Food Safety Training Logs and Videos

The food safety employee training video posted here is short and can help get you started! Employees can even view them on a cell phone.

Employee Training Video (CISA – English) – 9 minutes

Employee Training Video (CISA – Spanish) – 9 minutes

Health and Hygiene Training Log

Use this Training Log (Word) (.pdf) to record health and hygiene training activities that you carry out with your employees.

Job Specific Food Safety Training Log

Use this Training Log (Word) (.pdf) to record training on key good agricultural practices (except for employee health and hygiene training) that help protect against produce contamination on your farm.

Articles

Extension Services & Tools That Help NH Farmers Grow

Newsletters: Choose from our many newsletters for production agriculture

Receive Pest Text Alerts - Text UNHIPM to (866) 645-7010

This website is partially supported by the Food and Drug Administration (FDA) of the U.S. Department of Health and Human Services (HHS) as part of a financial assistance award #U2FFD007437-02. The contents are those of the author(s) and do not necessarily represent the official views of, nor an endorsement, by FDA/HHS, or the U.S. Government.